Testing & Commissioning

Testing

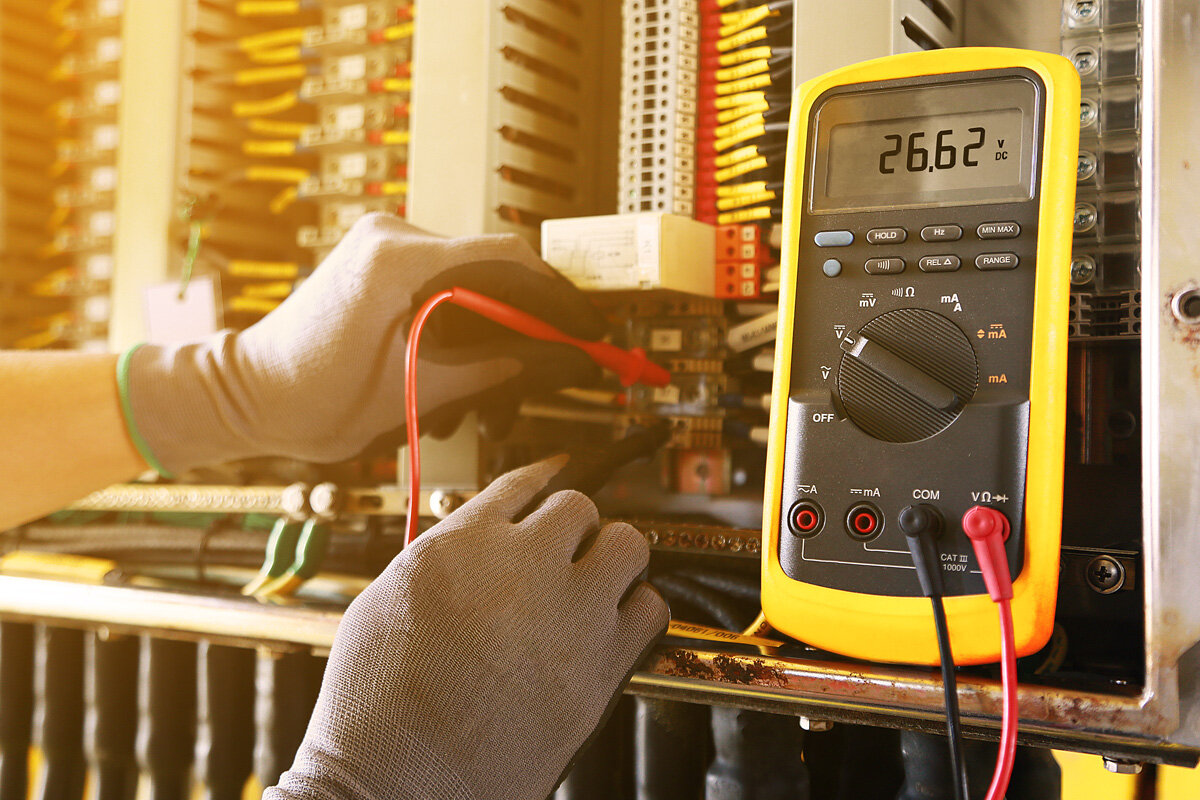

PELLINNO ensure all installations are tested in compliance with BS7671 and all manufactured systems are tested in compliance with BS6423, testing is conducted using UKAS traceable test instrumentation and certificates of testing are issued upon completion.

PELLINNO test engineers are electrically qualified and endorsed under the Electrotechnical Certification Scheme. For BS7671 Testing PELLINNO utilise editable forms from ECA Portal ensuring compliance at all times.

Full cable testing is completed in accordance with the requirements of BS7671, where cabling which is not covered under BS7671 this is all fully tested proving integrity of connections / interfaces. Cable test certificates are handed over upon completion.

Example of BS 7671 Installation Condition Report

System Testing

PELLINNO conduct full testing on panels / systems in accordance with BS6423 as required by the client, within this testing we would typically involve Torque Testing, Thermographic Imaging, Ultrasound, Primary and Secondary Injection Testing etc… Qualified reports for these tests are issued on completion. Process Instrumentation shall also be fully function tested where possible using UKAS traceable testing and measurement equipment typically: Pressure, Temperature, Flow, Levels etc...

Commissioning

PELLINNO Qualified and experienced personnel will support all phases of the commissioning process.

Our engineers are familiar with all aspects of LV Electrical Systems, Control Systems/Equipment.

Initial testing and commissioning requirements are determined within the design process and formal test and commissioning documents are issues to client for approval ahead of the works. The commissioning procedures are structured such that they also form a record of setpoints / configurations established and also the tests completed, it highlights associated actions and also presents a library of UKAS traceable test instrument certificates for instruments used within the testing, typically various testing is conducted eg;

Pressure Testing

Temperature Testing

Electrical Testing

Flow Meter / Switch Proving

UPS Testing (Battery Discharge)

Electrical Power Monitoring

Cable Testing

Thermal Imaging (Where Applicable)

Ultrasound Testing (Where Applicable)

Network Testing / Proving

Telemetry End to End Testing

Speed / Shaft Rotation Monitoring

Valve Positional Limit Setup / Testing

Analogue Signal Injection / Digital Signal Proving

Protective Device Primary and Secondary Injection

Gas Analyser / Detection System Testing (Using UKAS traceable specific gas compositions)

Level / Weight Measurement / Detection Instrument Proving

System Pipework Pneumatic / Hydraulic Leak Testing

Functionality Testing (Electrical Protection – Operational Controls – Emergency Shutdown Systems – Alarm & Trip Schedules -Motor Drives etc…)

Commissioning Procedures form part of the collective pack of design documents and revisions are all specifically document controlled as well as any drawing / documents referenced within throughout the entire process. The commissioning procedures are structured as follows and the documented pack is presented to the client upon completion of the works for their records.

Pre- Commissioning (Dead Systems - Non-Energised or Pressurised)

Commissioning (Live Systems – Energised and Pressurised)