Inspections & Calibrations

Owners and Directors alike are required to conduct Periodic Testing and Calibration to ensure safety to working personnel in accordance with the Health and Safety at Work Act 1974. It is the duty of company Directors / Senior Managers to implement such inspections which can be a recognition that worker personnel safety is being preserved and not compromised.

PELLINNO can advise our clients on what inspections and at what intervals these inspections need to be conducted in accordance with Industry Best Practice and in reference / compliance with the associated standards / regulations.

PELLINNO utilise qualified, competent, and experienced personnel to deliver Inspection and Calibration works as follows:

Periodic inspections and calibrations.

Hazardous Area Inspections to BS EN 60079-17

Visual/Close Inspections on certified equipment installed in Classified Hazardous Areas:

It is generally recommended that these inspections are conducted every 12 Months as a minimum

Detailed Inspections on certified equipment installed in Classified Hazardous Areas:

It is generally recommended that these inspections are conducted every 3 Years as a minimum

PELLINNO Qualified COMPEX Engineers would conduct these works.

Gas Detection Systems

Portable Gas Detectors: Certified Calibrations should be conducted Every 6 Months as a minimum – this can be tested at site or alternatively shipped to PELLINNO

Fixed Gas Detectors: Certified Calibrations should be conducted Every 6 Months as a minimum

PELLINNO Safety Trained Experienced and competent engineers would conduct these works.

Electrical Testing to BS7671

Minor Electrical Installation Works Certificate

Electrical Installation Works Certificate

Electrical Installation Condition Report (EICR) It is recommended that these are completed every 3 years on Industrial Systems

Earthing System Testing

PELLINNO Qualified Electricians would conduct these works.

Electrical System Testing to BS6423 – PELLINNO Report

CPD Primary and Secondary Injection

Thermal Image Surveys

Ultrasound Surveys

Power / Load Monitoring

Emergency Changeover / Shutdown Testing / Verification

PELLINNO Qualified Electricians would conduct these works.

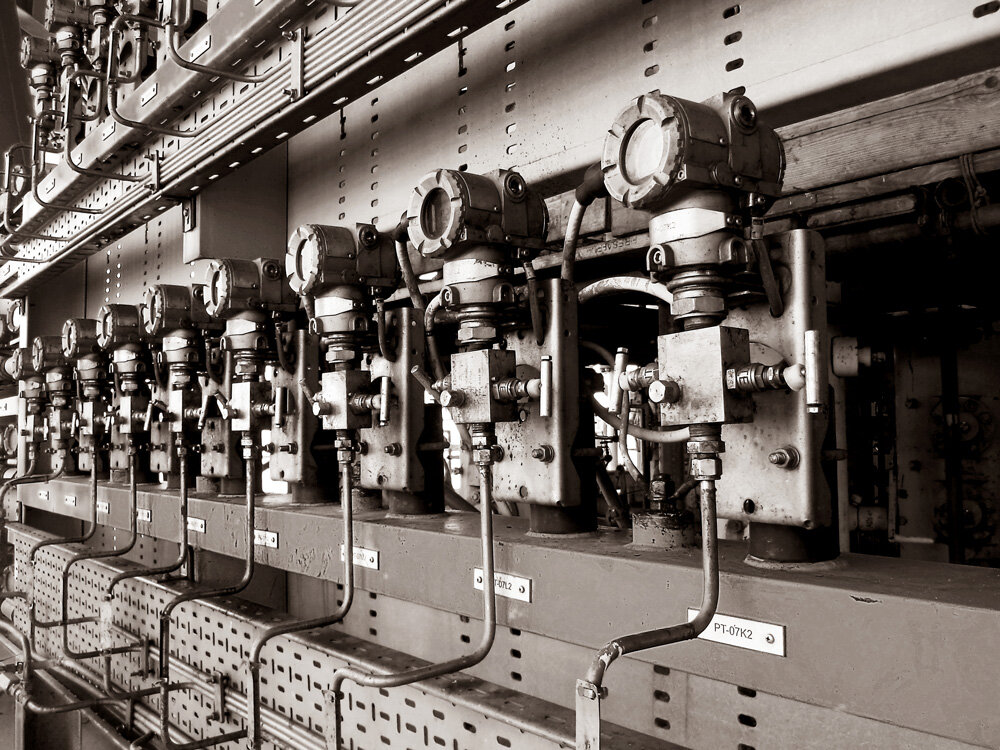

Process Instrument Calibrations

PELLINNO would use competent instrument engineers to deliver these works. PELLINNO have managed such works during shutdown periods where multiple instruments need to be tested. Each instrument tested / calibrated will labelled and also added to the Site Instrument Equipment Register. Certificates will be issued on completion of testing and where failures are determined the site management teams will be advised immediately.

All equipment is calibrated / tested using measurement and test instruments which are certified and traceable to UKAS Standards.

The range of Process Instrumentation which PELLINNO can functionally test/calibrate and/or prove are as follows, these can be tested in either hazardous or non-hazardous atmospheres, we utilise a range of certified test instruments including Hart Protocols to validate correct sensor device measurement.

Pressure

Temperature

Level

Flows

Gas Detection

Gas Analysers

In addition we would stroke/exercise any electrical and/or pneumatic control valves/actuators proving travel and limit functions etc…. We would also expect to run motors providing starter protection functionality and motor load verification.

Please contact PELLINNO to understand your requirements more fully or if you would like our engineers to draft a specific quotation which meets your requirements.